This article originally appeared in the September 2002 edition of Railway Bylines (Vol.7 No.10) and is reproduced here with the permission of the author and publisher. Railway Bylines is published monthly by Irwell Press, 59a High Street, Clophill, Beds MK45 4BE. You can find out more about Railway Bylines magazine at the publisher’s website: www.irwellpress.co.uk

Seaham Harbour, roughly midway between Sunderland and Hartlepool on the County Durham coast, had one of the best-known and best-loved industrial railway systems in the country. This celebrity status was wholly justified, not least of all because the system was home to a marvellous array of locomotives ranging from ex-‘main line’ tender engines to primitive vertical-boiler types. There was also vintage rolling stock – chaldron wagons were still in use in the 1970s. On top of all that, the system as a whole boasted a fascinating network of lines including much that was highly photogenic and wonderfully atmospheric.

The history of Seaham Harbour is very complex but, as it has been discussed in varying depths elsewhere, for the purposes of this article we will concentrate mainly on the working of the harbour railways. That said, a very brief potted history is in order, if only to explain the function of the harbour.

Background

Seaham Harbour was constructed by the 3rd Marquis of Londonderry as an outlet for the coal from his collieries, the original dock (the North Dock) opening to commercial shipping in July 1831. From the outset there was a rope-worked waggonway to convey coal from Londonderry Colliery at Pittington to the dock. As the local mining industry developed Seaham Harbour was extended and improved to keep up with the demand. A second dock – South Dock – was partly opened in July 1835, and there were further substantial extensions in 1902-05 and again in 1927/28.

An unmistakable feature of the harbour was the massive shipping staiths at the South Dock. Ultimately there were five such staiths: North Berth, Middle Berth, Pole Berth and Castlereagh Berth (all along the west side of the dock) plus the New Berth on the east side of the dock extension. Castlreagh Berth and New Berth were built of concrete with timber decking and top work whereas the other, older, staiths were timber set into concrete. Despite the decking timbers being 3″ thick, they were not immune to rot. Indeed, it was not unknown for an unwitting member of the railway staff to find one of his feet going right through them!

On the corporate front, in 1899/1900 the 6th Marquis of Londonderry reorganised his industrial interests. His public railway (the Londonderry Railway, the main line of which extended from Seaham to Sunderland) was sold to the North Eastern Railway, his collieries were vested in the newly-formed Londonderry Collieries Ltd, and the Seaham Harbour Dock Company Ltd was formed to administer Seaham Harbour. Four of the locomotives which had been part of the sizeable Londonderry fleet were transferred to the Seaham Harbour Dock Company.

By the early 1930s some 2¼ million tons of coal was being exported through Seaham Harbour annually. Some of it came from two of the local Londonderry-owned collieries – Seaham Colliery (connected to the harbour by a self-acting incline) and Dawdon Colliery (connected by a ¾ mile long branch) – but some also came by rail from South Hetton Colliery and Murton Colliery, both of which were owned by the South Hetton Coal Company.

That is how things remained until the National Coal Board came into being on 1 January 1947. The NCB took over the collieries and the railways which connected them to Seaham Harbour, but the harbour itself remained under Seaham Harbour Dock Company control. By this time it had a fleet of about a dozen locomotives

The harbour railways

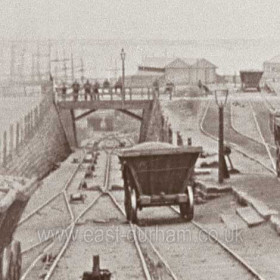

The harbour railways were divided into two main sections. The majority of the traffic was worked on the high level section which ran along a shelf on the cliff above the South Dock and extended southwards past the harbour along the coast to Nose’s Point (where ballast or spoil was taken for tipping into the sea). The high level section included the lines serving the shipping staiths. Railway wagons loaded with coal were run out on the staiths and the coal was tipped through the bottom doors of the wagons, via shutes, into the ships waiting below. After discharging, the empty wagons ran forwards, then ran back down a gradient into a hollow (invariably referred to as a ‘hole’). When a number of empties were ready they were collected by a locomotive and taken back to one of the inclines or to Dawdon Colliery or the LNER/BR exchange sidings near Dawdon Colliery.

On the low level section, some of the lines weaved along the quayside beneath the staiths. Their main functions were to enable coal which had been spilt from the staiths to be collected and, as there was no road access to the quays directly beneath the staiths, to deliver stores to ships. The low level lines also extended on to the breakwaters and were used to transport equipment and materials when the breakwaters required repairing.

The line connecting the low level to the high level was known as the ‘Dogger Bank’. It was a ferociously steep climb which, it is reckoned, was around the 1 in 11 mark. It is certainly the steepest bit of adhesion-worked line this writer has ever seen. Matters were not helped by the grass growing on the track and the fact that the line was accessed at the bottom by a short headshunt. There was no run-up here – the driver had to give an engine lots of steam, and hope! It was exciting to see this line in use as it ran along a ledge on the cliff face with a high retaining wall on the west side and an almost sheer drop on the other. More of this anon…

Locomotives

The Seaham Harbour Dock Company’s locomotive fleet included a number of veterans, several of which had interesting pedigrees. One of the most interesting of the early engines was No.1 SEATON. At the time the NER took over the Londonderry Railway in 1900, an 0 4 4T was under construction at the Seaham Engine Works (part of the Londonderry empire). This engine had originally been intended for passenger duties on the Londonderry Railway but, as the NER had ample passenger engines of its own and as there was no requirement for passenger engines on the Seaham Harbour railway system, the unfinished engine was taken to the Seaham Harbour Company’s new workshops to be completed as an 0 6 0T instead. When it eventually entered service, it was designated No.1 SEATON and had a works plate inscribed ‘Seaham Harbour Engine Works 1902’.

SEATON was kept in regular use at Seaham. Its 4ft 6in wheels meant that it was sluggish when pulling away but, once it got going, it was fast. Former Seaham Harbour Company driver Jimmy Taylor recalls that it was not a popular engine to work with – this was largely on account of its coil springs which made the ride somewhat lively. Jimmy also recalls that the engine was fitted with new cylinders, but these were smaller than the original ones and the engine was never as good afterwards. Previously it could get 20 empties out of one of the ‘holes’, but with the smaller cylinders it could manage only ten at a time. It was therefore necessary to make two trips to clear one of the ‘holes’ before a rake of twenty wagons could be assembled for forwarding to the south end sidings.

The harbour company also had four locomotives which were purchased from the North Eastern Railway. Among them was a tender engine named CLIO which had been built by the NER at Gateshead Works in 1875 and had been purchased in 1911. It was not altogether ideal for work at Seaham, its comparatively large wheels being unsuited to frequent starts on steep gradients with heavy trains; furthermore, the overall length of the engine and tender were troublesome when passing through sets of points. Surprisingly, though, there was little problem with the six-wheel tender derailing on the rough tracks. CLIO lay dismantled for many years finally being scrapped in 1955. Its tender was retained and used to transport water for cement making.

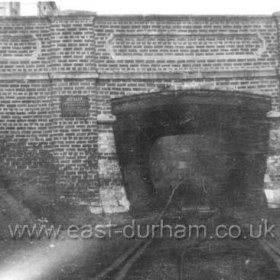

MARS and MILO were two other ex-NER engines. They were old Robert Stephenson 0 6 0STs of 1875 vintage but, despite their age, were well regarded and were used on the North Berth. They mainly handled chaldron wagons which came down the Seaham Colliery incline. The chaldron wagons (more of which anon) were retained for this duty on account of the low bridge at the foot of the incline.

Despite the small size of the chaldron wagons, the comparatively sturdy MARS and MILO often had difficulties getting sixteen or so of them out of ‘the hole’ at North Berth if the rails were greasy. Shunter Gordon Davison remembers having to get off the footplate and use a spanner to knock the sand pipes to try and get a flow of sand to the rails. On MARS and MILO this was a dangerous job as the sand pipes were behind the buffer beam under the overhang of the running board. Gordon learned of the dangers the hard way – on one occasion the end of the coupling rod hit him on the head and knocked him out. Fortunately, he fell backwards.

Former driver Jimmy Taylor remarks that the two saddle tanks had good enclosed cabs. This was in marked contrast to 0 6 0 tender engine CLIO which had a very spartan cab which offered scant protection against the elements.

There were also two Peckett 0 6 0STs which had been purchased new in 1905/06. Named SEAHAM and SILKSWORTH, they were not identical – the former was one of the maker’s ‘B2’ class with 14in cylinders whereas the latter was an ‘F’ class with 15in cylinders. The two Pecketts saw a lot of use but they were not held in particularly high regard as they were not as strong as some of the other engines. Although SILKSWORTH (which was known to the crews as ‘The Clogger’) was a good steamer, it could manage only eleven empties out of the holes. SEAHAM, on the other hand, was a poor steamer. It was generally considered that the deep firebox was a cause of over-firing – if too much coal were added it restricted the air flow through the fire. SEAHAM once shed one of its tyres and the rods were consequently removed. It ran for a while in this condition and, not altogether surprisingly, the adhesion was utterly hopeless. Jimmy Taylor referred to the Pecketts as ‘numb’ engines because they weren’t flexible to operate. A driver had to be careful with them to get the work done – it wasn’t just a case of throwing the fire on.

Among the other engines employed at Seaham was DICK, a small Hunslet 0 4 0ST which was used mainly on ballast work and for taking stores to ships in the dock.

In the opinion of the Seaham crews, the best engines the company owned were Hawthorn Leslie 0 6 0STs JUNO and NEPTUNE. These engines were powerful and were good riders. The two were not identical – NEPTUNE had smaller wheels and a higher boiler pressure. Of the two engines, the crews favoured JUNO. Jimmy Taylor confirmed that JUNO was a good steamer – with a load of empties up out of the ‘holes’ the injector had to be put on to prevent the boiler blowing off whereas, on the same work, NEPTUNE’s boiler pressure would drop. JUNO often worked at the south end of the harbour. Three engines were usually employed there.

.The ‘coffeepots’

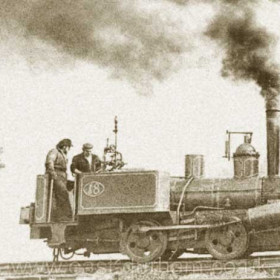

At Seaham, the age-old railway soubriquet of ‘coffepot’ was applied to two vertical-boilered locomotives (Nos.16 and 17) which had been built in the early 1870s by Head Wrightson of Stockton-on-Tees and the famous old Lewin 0 4 0 tank engine, No.18. These three locomotives looked after the work on the low level lines around the bottom of the staiths; they were the most suitable engines for that work on account of their small dimensions – some of the lines, particularly through the tunnels and under the staiths, had very limited clearances, and there were also some very tight curves which were too sharp even for ordinary 0 4 0STs .

The Head Wrightson locomotives were extremely basic machines. They had no cab so the driver had to stand on the framing and simply get on with it. One of the Seaham pair, No.16, had vertical cylinders and was geared but the other, No.17, worked in a more conventional manner. The gearing of No.16 sometimes proved troublesome – the cogs were mounted under the framing and therefore received a liberal helping of muck, while debris left between the rails presented another sort of problem.

Although No.16 was the better steamer, No.17 was the more powerful. If a driver had steaming problems with one of these engines the procedure was to lift the cover off the top of the boiler and clean the tubes. However, this usually resulted in the loosened soot being thrown all over the driver.

The Lewin (No.18) was, arguably, the most famous of all the Seaham locomotives. Built in 1877 (or so it is believed) as an 0 4 0 well tank, it had been twice rebuilt in the Seaham Dock Company’s workshops, firstly as a side tank and, in 1927, as a saddle tank. It was a remarkable veteran which positively oozed character. One of the former Seaham drivers, Hal Weetman, recalled the day when it suffered a bent coupling rod, the result of an altercation with some rocks on the beach. The rod was removed and taken to the workshops to be straightened, but this left the engine stranded on the beach (to the north of North Dock) and uncomfortably low on water. The only solution was to fill up with seawater until the repaired rod was brought back for fitting. The seawater might have been a quick solution, but it did little for the Lewin – the engine primed terribly.

The Lewin was regarded by the crews as a good little engine. It seemed to be going on forever – by the mid-1960s it usually worked the morning shift and finished about noon – but it finally succumbed in the early 1970s. Hal Weetman was working it at the time. There was steam blowing from the flange around the dome and Hal took the engine to the fitting shed where it was condemned on the spot. Thereafter lorries and dumper trucks took over the work.

The Lewin had gained the status of the oldest active steam locomotive in the country. After ceasing work it was laid aside at Seaham but in January 1975 it was taken to Beamish Museum for preservation. It was restored to its original condition with a well tank and no cab and, although it now looks very smart, there was a strong feeling among the Seaham crews at the time that it should have been preserved in its latter-day condition.

On the whole, the duties of the ‘coffeepots’ were fairly light. When not on ‘coal clearance’ work under the staiths the engines trundled around the low level lines with perhaps a couple of flat wagons, one loaded with cement and the other with a cement mixer. They would take the equipment to wherever maintenance work – repairing cracks in the harbour walls, for example – was being undertaken. In winter, damage to the breakwater and sea walls was common.

As for the repair work itself, the concrete was mixed on site at a depot near the low level engine shed. The engines were used to bring in wagons containing the cement (in bags) and also to take the finished blocks of concrete on flat wagons for storage. The sand, incidentally, was obtained from the beach to the north of the harbour and, as well as being used for block-making, it was also used for the engines sandboxes and for building work on the upper levels. The engines were also used for shunting the 5 ton cranes which were used to lift the concrete blocks.

Valve trouble

As on almost all railway systems everywhere, the engine crews sometimes resorted to unofficial methods to keep their charges working. At Seaham, the Head Wrightson locomotives came in for such treatment. The men used to weight the engines’ safety valves either by holding on to them or, as increasingly became the practice, by placing a chain on the safety valve lever. In the case of No.16 this was not to get extra pressure, but because of a fault with the safety valves – they hadn’t been properly ground into the casting so steam continually by-passed them. No.16 ran around with the chain permanently on the valve lever as, otherwise, there simply wasn’t enough pressure for the engine to do any work. Jimmy Taylor reported this to the foreman fitter, but nothing was done to repair the fault.

Although the weighting down of the valves was common practice and was known to the management, it was quite unofficial. Indeed, on one occasion Jimmy Taylor was suspended for several months for having resorted to the practice despite the fact that, when his boss was riding on the footplate, he would hold the safety valves down for Jimmy as the driving position was on the other side of the footplate to the safety valve lever!

Nevertheless, the vertical-boiler engines carried on having their safety valves held down until the end of their days. The Lewin (No.18) escaped such treatment as its safety valves couldn’t be weighted.

An accident

Jimmy Taylor recalls one tragic incident which took place in about 1946. He was driving ‘coffeepot’ No.16 which had taken the 5 ton crane out to the south breakwater where repair work was needed. In the customary manner, the crane driver was accompanied by a ‘crane lad’ who, besides helping, was learning how to operate the crane. While the work was in progress Jimmy had to take No.16 to the high level to get lubricating oils and hand cleaning aids, leaving the ‘crane lad’ driving the crane which was pulling a flat truck loaded with blocks. The crane toppled over the wall on to the beach, taking the flat wagon with it. The blowdown valve of the crane was knocked off and allowed steam to rapidly escape from the boiler – the crane driver was very badly scalded.

he ‘crane lad’ also went over the wall – he was trapped under the boiler and the driver, despite his own appalling scalds, told the first men on the scene to “see to the bairn”. Unfortunately, the ‘crane lad’ was dead. The driver himself died of his injuries a couple of days later. There was a third casualty – a workman had been standing on the wagon attaching the blocks on to the crane hook went over the wall as well. He was badly injured.

Sentinels

In the autumn of 1956 the Seaham Harbour company had a two-year-old 200hp Sentinel on trial. It would seem that the management was impressed as the company soon purchased the locomotive. Two similar Sentinels were purchased new in 1956/57. However, even if the management had been optimistic about the locomotives, the crews were distinctly unimpressed. The locomotives might have had adequate power for ordinary requirements, but for the type of work they had to undertake at Seaham they were short on adhesive weight and they were particularly unsuited to the gradients. Jimmy Taylor recalls that a lot of trouble was experienced with the boilers – they would sometimes become red hot and would start to bulge under the high pressure of 225lbs. Jimmy opines that the water space was not large enough and that, on the gradients and undulating track, the top of the boiler would be uncovered. This meant that the red hot plates were constantly been covered and uncovered by water. Some of the shunts required sudden bursts of power followed by coasting down hill – this did the engines no good at all. Indeed, when a visiting insurance inspector saw the boiler plates glowing a dull red and bulging he stopped the locomotives from being used.

As will be seen in the accompanying summary of locomotives, one of the Sentinels was returned to the maker in 1958 and, the following year, another went to Thomas Hill where its frame and wheels were reused for its ‘conversion’ to a 4 wheeled diesel-hydraulic.

1960s acquisitions

As the years progressed an increasing amount of Seaham’s rail-borne traffic was handled in larger steel-bodied wagons, and many of the smaller and older Seaham locomotives with lower boiler pressures were found wanting. To keep up with traffic requirements the harbour company looked to the second-hand market and, between 1960 and 1963, purchased no less than seventeen steamers from other local industrial concerns. These proved to be a mixed bag: some were good but others were clapped out.

At the ‘more useful’ end of the scale were five Hawthorn Leslie 0 4 0STs purchased from the Consett Iron Company in 1960. Four of these had 16in cylinders and proved to be good, powerful engines which were capable of lifting up to twenty empties at a time out of the ‘holes’. Despite the engines’ usefulness, the crews reckoned that they weren’t as comfortable to work on as JUNO and NEPTUNE. The other Hawthorn Leslie purchased from Consett was a smaller 14in example. It, too, proved to be a useful acquisition – at least, it was until it was converted to oil-firing in the early 1960s. As an oil-burner it gave a lot of trouble with fuel leaks on the footplate and fumes. There were also complaints about the noise made by its burners.

Two other second-hand Hawthorn Leslie 0 4 0STs came from the South Durham Steel & Iron Company’s works at West Hartlepool. These bore Nos.1 and 3. None of the Seaham men this author has spoken to remembers No.1 working, but it is known that No.3 did work at Seaham.

Dorman Long was the source of eight very squat but very large 0 4 0STs – four came from DL’s Acklam Works and four from Britannia Works, both premises being in Middlesbrough. These engines might have been satisfactory on the flat, moving slowly with heavy loads, but they were no good charging steep gradients at Seaham. They were poor steamers – heavy loads could often be moved only a few hundred yards before steam ran out. It is believed that only some of the eight were ever put to work at Seaham, the others being merely a source of spares.

The crews were distinctly unimpressed with these engines, especially the very cramped cabs.

The largest second-hand acquisition of the period was Manning Wardle 0 6 0T No.44. This engine had started life as a saddle tank but had been substantially rebuilt and fitted with side tanks at the NCB’s Lambton Engine Works in 1951. With its narrow cab, high dome and big tanks it was an aesthetic disaster. The Seaham Harbour company purchased it from the NCB in February 1960, it having latterly been based at Philadelphia for use on the old Lambton Hetton & Joicey system. Opinions differ about this engine. Some of the older Seaham drivers liked it but some other drivers reckoned it was a big clumsy lump. The shunters didn’t like the height off the ground – if they missed their footing it was a fair way down.

Diesels

As can be seen from the accompanying table, five English Electric 305hp diesel-hydraulics were purchased new in 1967. Before long they were painted light blue with yellow cabs. They might have looked fairly dainty but, in practice, they were very powerful and efficient. The diesels were housed in a lengthy single-road shed; this was something the steamers had never experienced – the old steam ‘shed’ had had walls and window frames, but no roof.

The diesels displaced the steamers and, with one exception, the remaining steamers were scrapped en masse during 1967. The exception was the little Lewin which was retained to handle the breakwater repair trains. As noted earlier, it finally ceased work in the early 1970s.

Chaldron wagons

A familiar feature of the Seaham Harbour railway scene was the chaldron wagons, invariably known at Seaham as ‘black wagons’. They had bottom-emptying doors suitable for discharging their loads at riverside staiths. They had been widely used for coal traffic since the days of the early waggonways, and until the early 1900s were also used by the ‘main line’ railway companies.

On the Seaham system the standard chaldron had a tare weight of about 2½ tons and a capacity of four tons. Some of the Seaham chaldrons remained in use until the 1970s – it is thought that they were the very last in regular use anywhere in the country – though latterly they were used mainly as mobile rubbish skips.

That said, until the 1960s the chaldrons were also used for coal collection. To explain… With such huge quantities of coal being shipped – even in the 1960s almost 1,500,000 tons was exported through Seaham annually – there was inevitably some spillage. This was collected from beneath the staiths and loaded into chauldron wagons. Being small, they could be loaded by shovel.

Staffing

In the 1950s and ‘60s seven engines were in use each day. Six of these were out on two shifts: 6am-2pm and 2-10 p.m. The late shift often stayed on until midnight if work demanded, for example to finish loading a ship so that it could make the tide. Also, at least one engine usually worked until midnight on spoil tipping duties. The seventh engine in steam each day worked the low level lines around the bottom of the staiths.

The Seaham crews tended to work on a six-week cycle with two weeks on each job; so it would be two weeks on the North End, two on the South End then two on the Low Level lines. The men driving the ‘coffeepots’ were often firemen on the top lines – the ‘coffeepots’ were suitable for the less experienced because of the light duties they performed.

As well as the engine crews there were two sets of platelayers with 8 to 10 men in each gang. All told, in the 1960s the dock company employed 340 men including engineers, coal trimmers, tug and dredger crews, administrative staff etc.

‘Dogger Bank’

Various mentions have been made of the ferociously-graded ‘Dogger Bank’ – the connecting line between the low level and the high level systems. Sanding was very important while working the Dogger Bank. Besides having sand in the engine’s sandboxes, an old 5 gallon drum was carried which also contained sand. In difficult conditions a shunter could grab a handful of sand from the drum, jump off the engine and get the sand on to the rails.

Before taking cranes down the bank it was good practice for an engine to go down light engine and apply sand to the rails, then come back up to collect its train. If the rails were really bad a sprag was pushed into the wheels of the wagons to lock them; this was a sensible safety precaution as the ‘black wagons’ had rather inefficient brakes while the flat wagons had none at all. On one occasion Hawthorn Leslie No.10 was making its way up the bank pushing a couple of ‘black wagons’ when a tube burst. This put out the fire and the boiler pressure plummeted, rendering the engine useless until repaired. JUNO went down and pulled the trucks and loco up.

On another occasion SILKSWORTH had just negotiated the worst of the climb when the coupling to the first wagon broke. Three wagons carrying sand, cement, a cement mixer and other equipment went hurtling down the bank to land up in wild abandon at the bottom with wood, sand and bits of equipment everywhere. The crews found that the best engines on the Dogger Bank were JUNO or NEPTUNE which could get five or six Black Wagons of spillage up the bank.

Although the railway work at the low level usually fell to the ‘coffeepots’, if anything more than a couple of empty flat wagons needed to be taken up the Dogger Bank this was beyond the engines’ capabilities so the wagons were left in the headshunt to be collected later by a larger engine. The Lewin (No.18) exhibited a waggling gait when working the Dogger Bank. Hunslet 0 4 0ST DICK used to display a different phenomenon when on the bank – despite having a long, narrow chimney the exhaust would go, not straight up in the air, but to the sides. Even more curious was that three puffs would go to the right and the next would go to the left!

Reports of visits to Seaham Harbour occasionally appeared in the railway press. These two featured in the Railway Observer.

10 August 1955: ‘Ex-North Eastern Railway 0 6 0ST Mars was noted shunting colliery tubs on the harbour lines. It works a double shift, a day of sixteen hours. In comparison with similar engines at Backworth Colliery, Mars appears to be in its original condition with Salter safety valves and an old type cab, while the name Mars is in bold letters on an oval nameplate similar to the old NER numberplate and in the same position as the latter on the cab sheets’. (A subsequent report added that the nameplate of Mars – and also that of Milo – were in fact the old NER numberplates with the numerals removed and the letters substituted.)

28 December 1966: ‘The following were noted at the company’s shed: Nos.3, 10, 18, 38, 173, 177, 183. There were two further 0 6 0STs and an 0 4 0 lying out of use but unidentifiable. The interesting 0 4 0ST, No.18, built by Lewin of Poole, was also out of use. Most of the remaining locomotives in steam were in deplorable external condition. Work was in hand on diesel stabling facilities and one diesel shunter was noted working at the docks…’

Maintenance

The loco water at Seaham was very hard so good washouts were imperative. Tablets were added to the water to try and alleviate the problems, but this was not a long-term solution. Indeed, on one occasion No.38 suffered a bulge in the side of its firebox; usually, a patch would have put over the bad area once it had been re-stayed, but the boilersmiths let in a new patch having cut out the overheated section and welded the patch and fixed new stays. The workmanship was first class. The engine was also overhauled with a new pumped oil supply to all the axleboxes, cylinders, slide bars and valve chests. It ran superbly. Other engines were similarly equipped when they were overhauled.

The locomotive maintenance staff were always held in high regard by the crews, but towards the end of steam working at Seaham a corporate reluctance to spend money on soon-to-be-replaced equipment meant that the engines became very run down. Steam and water leaks in boilers were becoming endemic. When an engine started popping tubes or the ferrules on the tubes needed replacing, the job was hampered by the arch in the firebox; sometimes, the boilermen’s solution to this problem was to knock out the arch. However, the brick arch had been there for a purpose – it not only caused better combustion and greater efficiency in the amount of coal used, but it also protected the tube ends. Furthermore, the heat it retained caused slower cooling of the firebox when the engine had its fire thrown out at the end of a day’s work.

The removal of the arch might have solved one problem but it created others – for example, JUNO and NEPTUNE both suffered cracks in the top corners of the firebox. The crews were trying to work a heavy shift with copious amounts of water running into fireboxes. Keeping steam and water levels up in such circumstances was very difficult. From the crews’ point of view, the arrival of the diesels came as a blessed relief.

Decline

Throughout its long life Seaham Harbour had relied almost exclusively on only one commodity – coal. That situation proved to be the port’s downfall as, when the coal industry started to decline, so did the harbour. Another factor working against Seaham was that the largest ships it could accommodate were a fairly modest 4,500 tons deadweight. Other ports in the north-east – Sunderland, Newcastle and Blyth – could handle much larger vessels.

Indeed, the CEGB had invested in new ‘super colliers’ that were up to the maximum size that could be handled at Sunderland and at Harton Staiths on the Tyne, and it became the usual practice for coal from the collieries at Seaham to be taken by MGR train to the Tyne for shipment.

In 1978 the NCB ceased using Seaham for shipping coal and the staiths were soon demolished, thereby dramatically changing the appearance of the harbour. But despite the loss of the coal traffic the harbour company – to their credit in difficult trading circumstances – succeeded in attracting some new trade: steel came for export and there were even some imports. However, with the exception of the steel, all the newfound traffic was moved by road, so the harbour railway system saw less and less usage.

By the 1980s the principal traffic handled at the harbour was stone or colliery waste. Mechanisation of coal cutting produced huge quantities of stone and, at one time, Dawdon, Vane Tempest, South Hetton and Murton collieries all disposed of their spoil at Seaham. There was also the steel traffic (mainly from BSC Teesside), though from the railway’s point of view this offered only occasional activity.

Wagons of steel arriving for export were accepted at Seabanks signal box and moved by the diesels to the dock company offices. Here the steel was loaded on to lorries to move it down to the berths for loading. When a steel shipment came, four of the five diesels might be in use; at other times three sufficed – two at the Dawdon end and one to and from the incline to Seaham Colliery.

During the 1980s and 1990s the local mining industry contracted. In February 1982 Vane Tempest and Seaham collieries merged, with Seaham becoming the coal winding and washing plant. Traffic from South Hetton Colliery ceased in 1984, the incline from Seaham Colliery to the harbour closed on 17 July 1987 (when BR took over responsibility for coal and spoil traffic), Dawdon Colliery closed in July 1991, and the ‘combined’ Seaham and Vane Tempest collieries were mothballed on 23 October 1992. They were officially closed in May 1993.

Although Seaham Harbour no longer handled coal exports, the contraction of the local mining industry nevertheless had a knock-on effect at the harbour. This meant that the fleet of five diesels was over-large, so one of the five was scrapped in 1988 and two were sold in 1989. The other two diesels (D4 and D5) remained on site for the steel traffic, but that traffic ceased in 1992 and the two locomotives were mothballed in the vain hope that they would be needed in the future. That did not happen, and in 1994 they were sold to the scrap merchants C.F.Booth of Rotherham.

Seaham Harbour is still in commercial use today; imports include forest products, fertiliser, steel and sand, and exports include limestone and wood chips. The harbour has modern container handling and bulk loading facilities, but none of the traffic arrives or departs by rail.

Contributor’s note: I would like to thank Stan Rogers, Gordon Davidson, Jimmy Taylor, Jimmy Price, Hal Weetman, Eddie Mayhew and Roy Hanson for their help with the preparation of this article. Reference was also made to Industrial Locomotives of Durham (Industrial Railway Society, 1977), Steam Railways in Industry by H.Gamble & C.T.Gifford (Batsford, 1976) and Industrial Railways of Seaham by A.J.Booth (Industrial Railway Society, 1994).

Thanks also to Colin Mountford for locomotive information. SEAHAM HARBOUR DOCK COMPANY – summary of locomotives (listed in order of acquisition)

Makers abbreviated thus:

BH – Black Hawthorn; BT – Blyth & Tyne Railway (Percy Main Works); EE – English Electric (Vulcan Works); HE – Hunslet Engine Co; HW – Head Wrightson; MW – Manning Wardle; NE – North Eastern Railway (Gateshead Works); P – Peckett & Sons; RS – Robert Stephenson; RSH – Robert Stephenson & Hawthorns; S – Sentinel; SH – Seaham Harbour Dock Co; SL – Stephen Lewin; TH – Thomas Hill; TR – Thomas Richardson; YE – Yorkshire Engine Co